technological innovation

Coated abrasives structure

Front:

Coated Abrasives, commonly known as emery cloth or sandpaper, are made by bonding abrasives to flexible materials such as cloth and paper with a binder. They have various shapes and are characterized by flexible grinding and polishing. They are flexible and foldable.

Content:

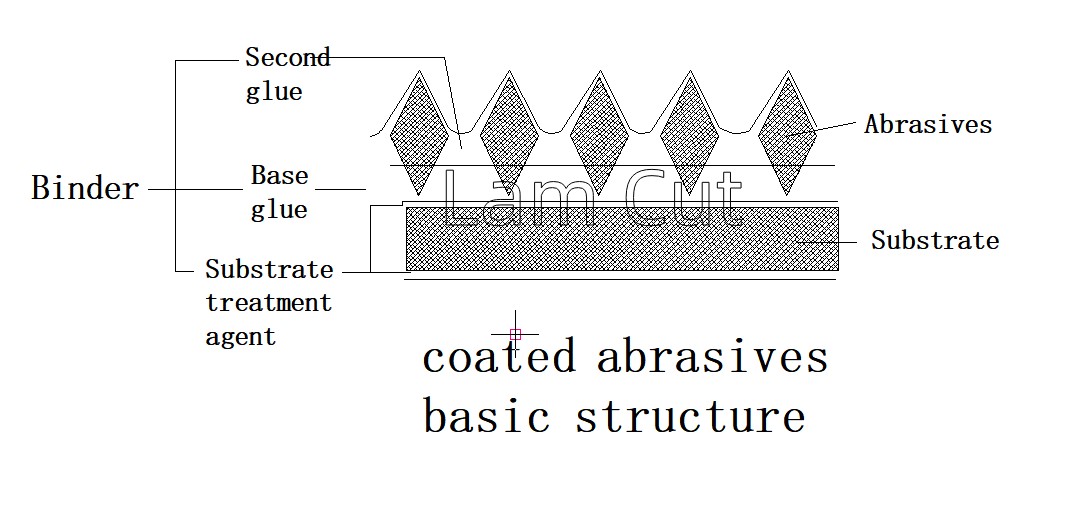

Coated abrasives are composed of three parts: Substrate, Abrasive and Binder, which are the three elements of coated abrasives.

Basic structure of coated abrasives:

Abrasive - As the cutting edge, it plays the leading role in grinding and is the most important factor in the grinding tool.

Substrate - the carrier of abrasive and binder. It is the dominant factor that distinguishes coated abrasives from other abrasives and makes them flexible.

Binder - the dominant factor that bonds the abrasive to the substrate to give it a certain shape and strength. It is mainly divided into base adhesive, double adhesive, substrate treatment adhesive and conversion adhesive.

The abrasive grains of coated abrasives are evenly distributed on the surface of the substrate, basically in a single layer. The electrostatic sand planting process ensures that the sharp corners of the abrasives face outwards, and the abrasives are oriented and arranged at the same height. The directional arrangement and equal height of the abrasive grains on the surface of the coated abrasives give the coated abrasives high efficiency and cold grinding characteristics.

The characteristics of coated abrasives and their performance as grinding and polishing tools are mainly determined by the following nine factors: substrate, substrate treatment, abrasive, particle size, sand density, binder, bond strength, shape and size.

Abrasives---Types of abrasives. There are two major categories: natural abrasives and artificial abrasives. Natural abrasives include natural corundum, garnet, etc., and artificial abrasives include corundum, silicon carbide, etc.

Grain size - It is expressed in terms of abrasive particle size, which indicates the size of the abrasive particles.

Sand planting density refers to the density of abrasive distribution on the surface of the abrasive tool, which is expressed as the coverage rate of abrasive on the substrate per unit area. It is divided into two categories: sparse type and dense type. There are also three categories: sparse type, medium type (semi-sparse type), and dense type. It is equivalent to the organization of the grinding wheel.

Substrate - There are mainly paper, cloth, steel paper, composite substrate, non-woven fabric, polyester film, etc. Each substrate has several grades due to its unit weight, strength, thickness, composition, etc.

Substrate treatment - the method of treating the substrate with a substrate treatment agent. Due to different substrate treatment processes, the same substrate can be processed into several varieties. There are also some substrates, such as paper, steel paper, etc., which do not require substrate treatment.

Binder - Types of binders include animal glue, semi-resin, full resin, water-resistant, etc. Its materials mainly include animal glue, synthetic resin and paint.

Bond strength - the degree of bond between the abrasive and the substrate. It can be seen as the difficulty of the adhesive resisting the external force to cause the abrasive to fall off the surface when the external force acts on the surface of the abrasive, which is similar to the hardness of the grinding wheel.

Shape - The shapes of coated abrasives mainly include pages, rolls, belts, discs and wheels.

Size - the size of the abrasives.

Due to the differences in the three major components and nine major elements of coated abrasives, there are many varieties of coated abrasives, which can be selected according to the grinding objects and grinding conditions.

RELATED NEWS

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Sarah Qi

Phone: +86 15189245666

E-mail: info@abrasives-machinery.com

Whatsapp:+8615189245666

Add: No.1 Chengxiang Rd,Dagang Town,Yandu District,Yancheng ,Jiangsu,China.